あなたがオーケストラを指揮していると想像してください。ミュージシャンに「大きく」または「静かに」演奏するように指示するだけではなく、「もう少し小さく」、「徐々に大きく」、または「その音量を維持して」と微妙な手のジェスチャーを指示します。油圧比例バルブは作動油の導体のようなもので、単なる「オン」または「オフ」ではなく、無限に可変の制御を提供します。

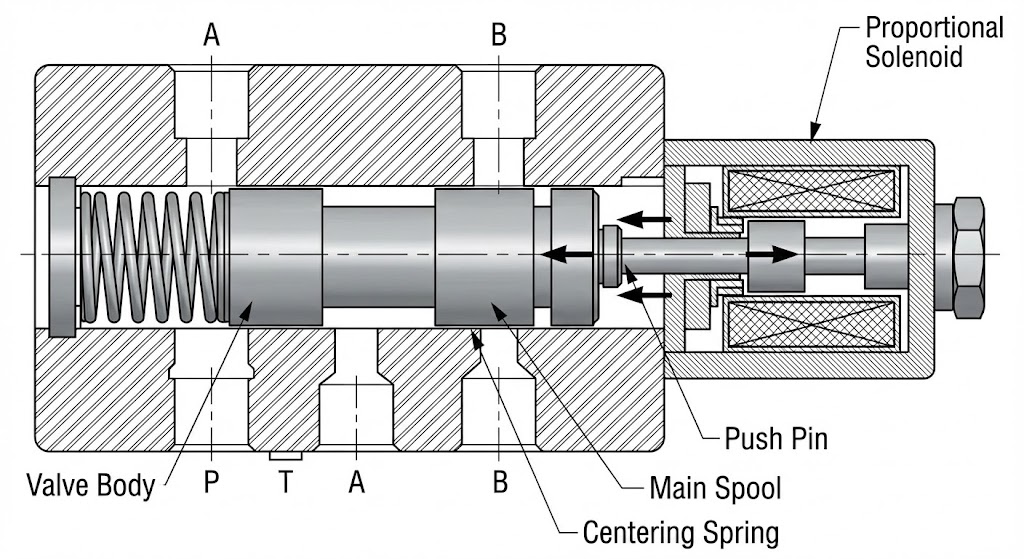

油圧比例バルブは、電気信号を正確な油圧流量、圧力、または方向制御に変換する電気油圧制御デバイスです。全開または全閉のいずれかである従来のバルブとは異なり、比例バルブはこれらの両極端の間の任意の位置を維持することができ、スムーズで正確な制御を実現します。

基本については、以下から始めてください比例弁とは何ですか.

- 01どのように機能するのでしょうか?

- 02比較: オン/オフ、比例、サーボ

- 03比例弁の種類

- 04性能特性

- 05実際のケーススタディ

- 06セレクションガイド

油圧比例弁はどのように動作するのですか?

電気信号から正確な油圧動作までの制御の流れをたどってみましょう。

[詳しい説明はこちら]比例弁の仕組み。]

現実世界の例:掘削機のオペレーターがジョイスティックを途中まで動かすと、比例バルブは 50% 信号を受信します。スプールは、油圧シリンダーへの最大流量のちょうど半分を許可する位置に移動し、その結果、アームの動きが正確に半分の速度でスムーズに制御されます。

比例弁 vs サーボ弁 vs オン/オフ弁

正しい選択をするには、バルブ タイプの違いを理解することが重要です。

| 特徴 | オン/オフバルブ | 比例弁 | サーボバルブ |

|---|---|---|---|

| 制御タイプ | バイナリ (オープン/クローズド) | 無限の位置決め | 超高精度の位置決め |

| 応答時間 | 10~100ミリ秒 | 5~50ミリ秒 | 1~10ミリ秒 |

| 正確さ | ±5~10% | ±1~3% | ±0.1~0.5% |

| 料金 | 50~500ドル | 500~5,000ドル | 直線性 (±0.5% ~ ±3%): |

| エネルギー効率 | 貧しい | 良い | 素晴らしい |

- 次の場合にオン/オフ バルブを選択します。単純な起動/停止制御で十分である、予算が非常に厳しい、または環境が汚い。

- 次の場合に比例弁を選択してください。可変速度/圧力制御が必要であり、エネルギー効率が重要であり、スムーズな操作が重要です。

- 次の場合にサーボ バルブを選択してください。超高精度が重要であり、非常に高速な応答が必要ですが、予算によっては最高のパフォーマンスが可能になります。

油圧比例弁の種類

機能別: 3 つの主要なカテゴリ

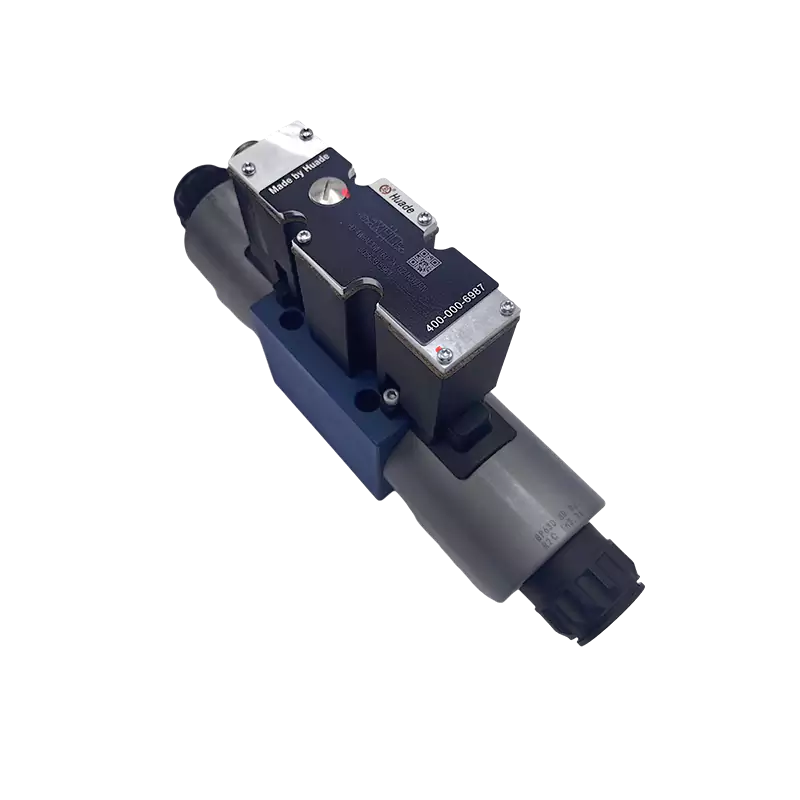

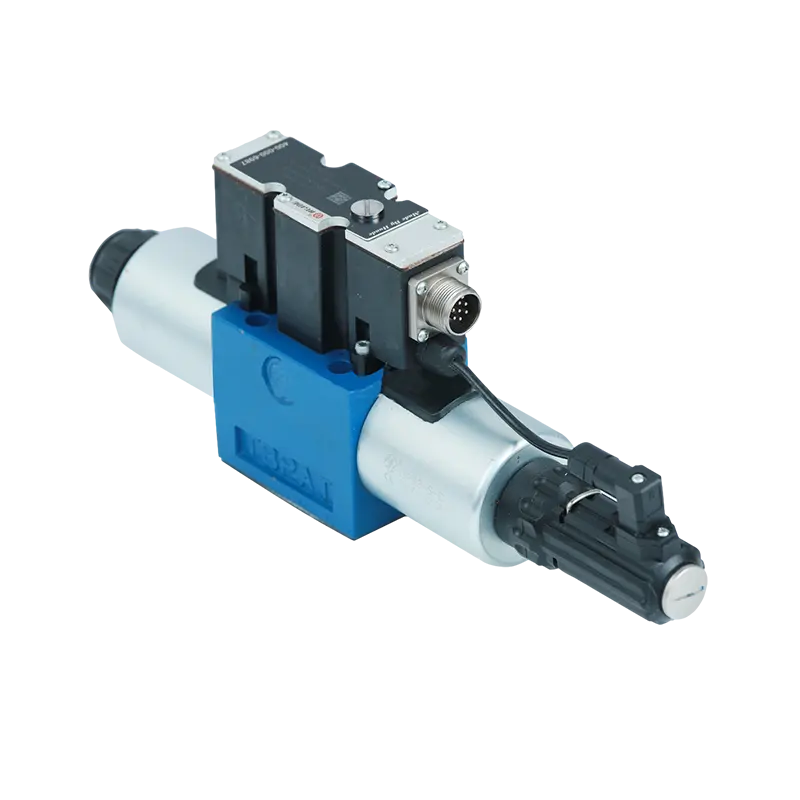

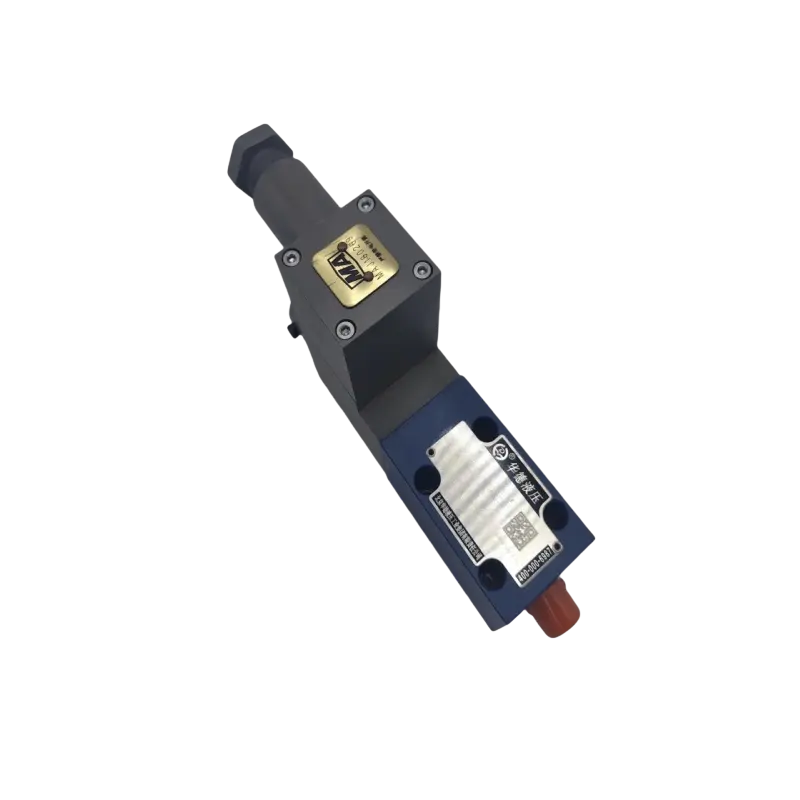

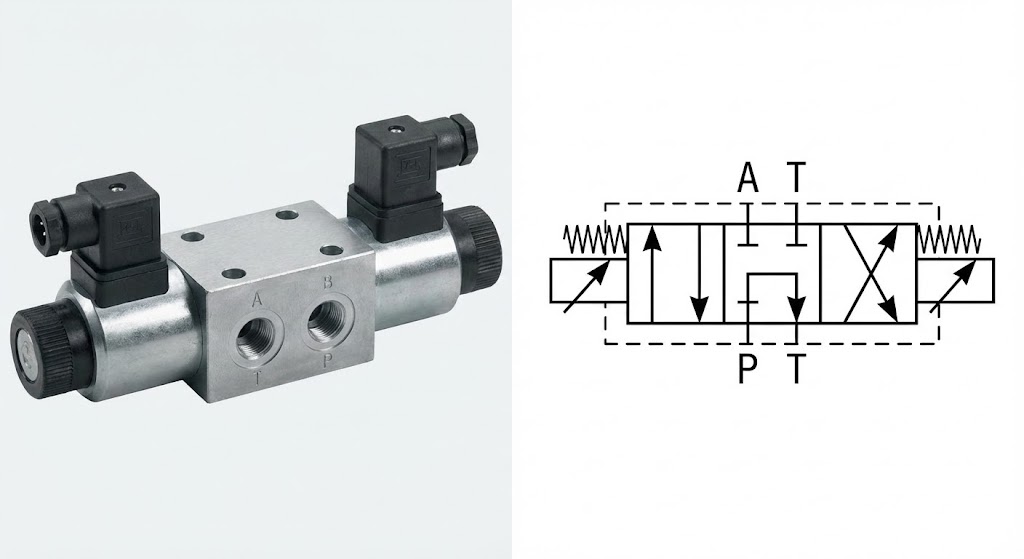

1. 比例方向制御弁

彼らがやっていること:油圧アクチュエータの方向と速度の両方を制御します。

次のように考えてください。交通を誘導するだけでなく、速度制限も制御するスマート交通管制装置。

以下に最適:工作機械、射出成形、オートメーション全般。

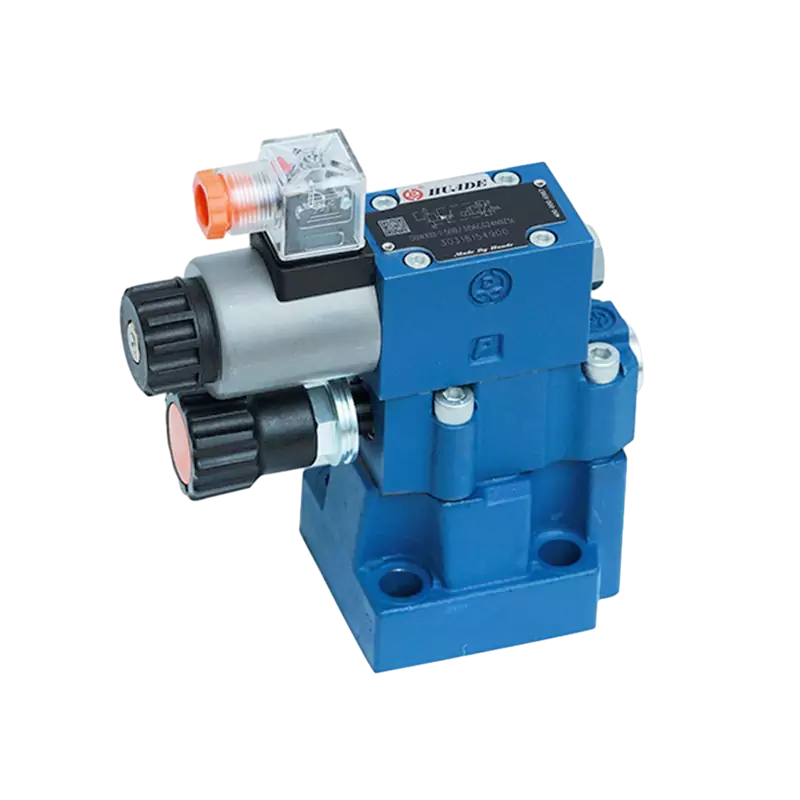

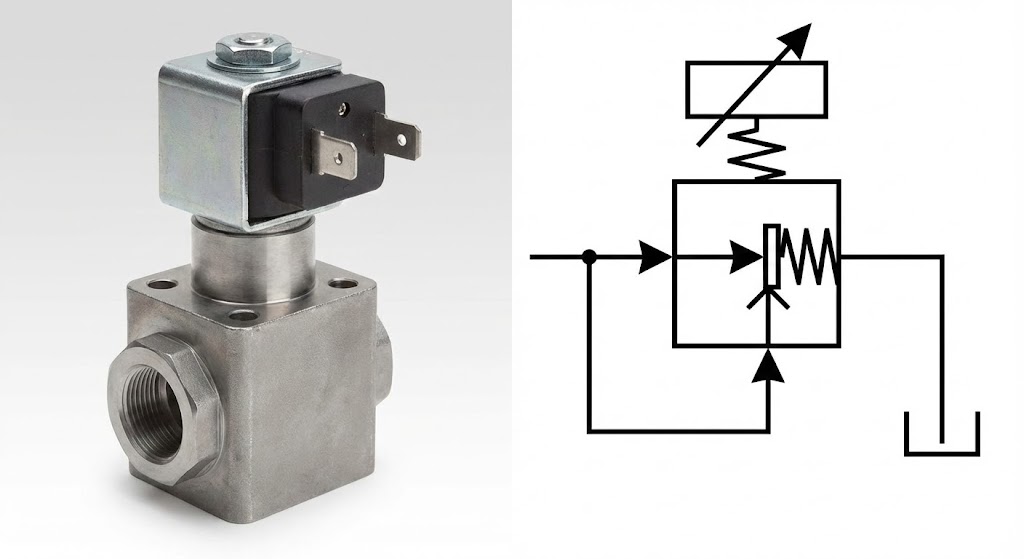

彼らがやっていること:流量要求に関係なく、正確なシステム圧力を維持します。

次のように考えてください。誰かが食器洗い機のスイッチを入れた場合でも、シャワーの圧力を完璧に保つスマートな水圧レギュレーター。

以下に最適:プレス操作、クランプシステム、圧力試験。

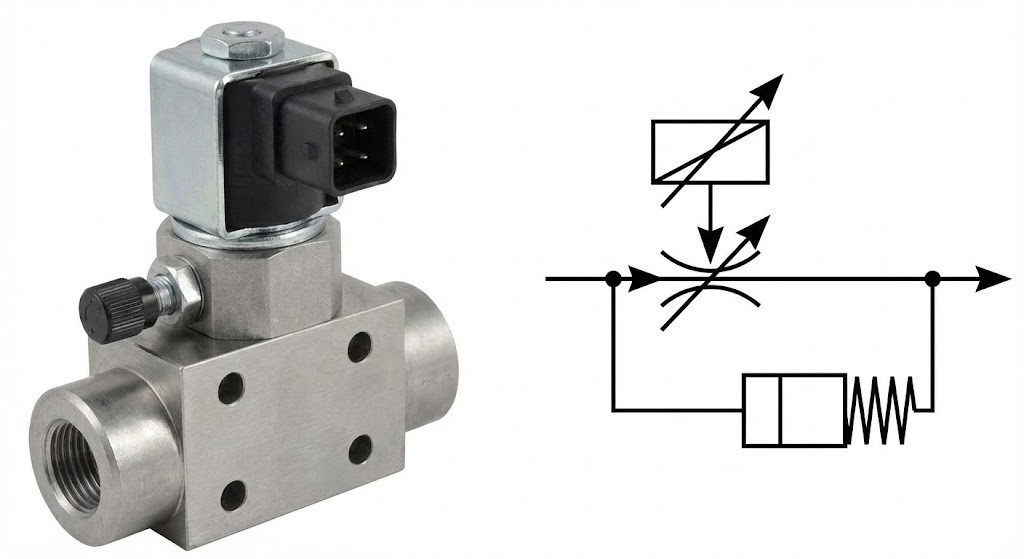

彼らがやっていること:圧力変化に関係なく正確な流量を維持します。

次のように考えてください。油圧流量のクルーズコントロールシステム。

以下に最適:速度制御、同期運転、計量アプリケーション。

構造別: 力学を理解する

-

直動式比例弁:電磁石によりメインスプールをダイレクトに駆動します。構造が簡単になり、コストが下がります。中規模のアプリケーション (最大 100 GPM) に最適です。

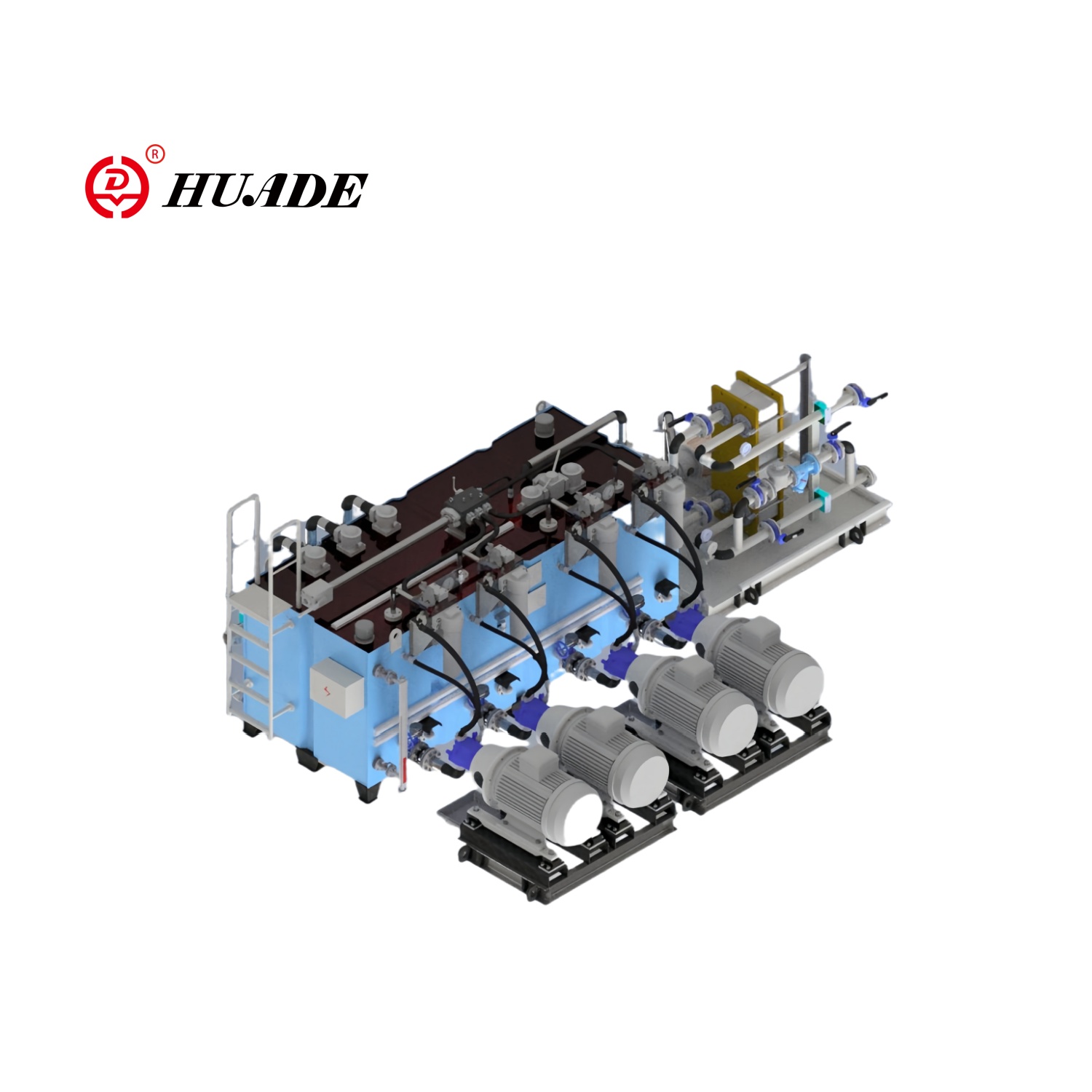

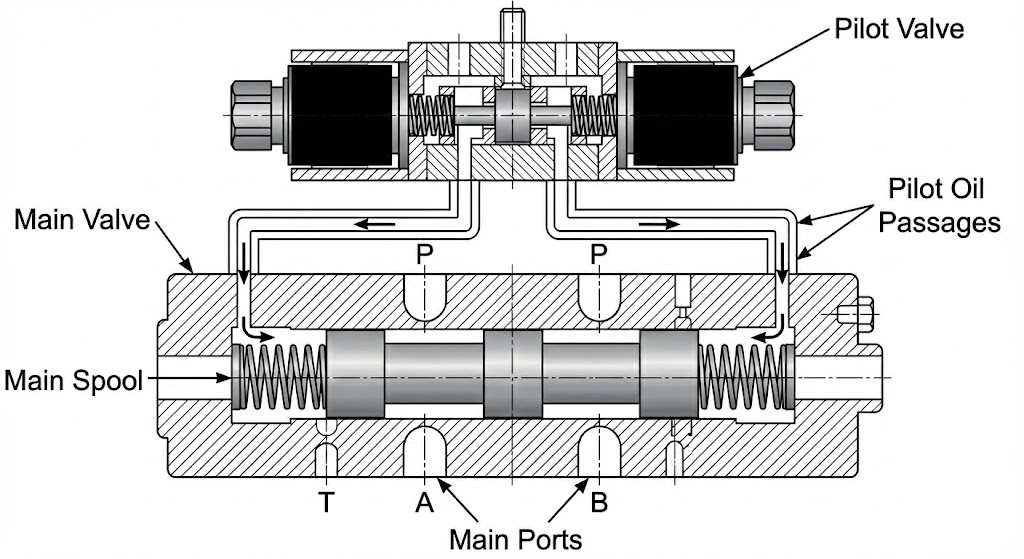

- パイロット操作式比例弁:小型のパイロットバルブがメインバルブの動作を制御します。より高い流量 (500+ GPM) と圧力機能。大規模な産業システムに最適です。

重要なパフォーマンス特性

比例バルブの性能の核心は、電気信号を油圧出力にいかに正確に変換するかにあります。

- 直線性 (±0.5% ~ ±3%):方眼紙に直線を引くことを想像してください。直線性は、バルブの実際の性能がその完璧な直線にどの程度近づいているかを測定します。

- ヒステリシス (±0.5% ~ ±5%):これは、異なる方向から同じ設定値に近づいたときの出力の違いを測定します。ヒステリシスが少ないほど、より正確な制御が可能になります。

- 再現性 (±0.1% ~ ±2%):バルブはどの程度一貫して同じ動作を実行しますか?優れた再現性は、より信頼性の高いパフォーマンスを意味します。

- 応答時間 (5 ~ 100 ミリ秒):バルブは信号の変化にどれくらい早く反応しますか?応答が速いため、システムの不安定性が防止されます。

最大システム圧力 (PSI)

Q = Cd × A × √(2ΔP/ρ)この式は、比例弁がなぜ非常に効果的であるかを示しています。領域 (A) を正確に制御することにより、圧力変動に関係なく正確な流量制御 (Q) が提供されます。

実際の成功事例

ケーススタディ 1: 射出成形革命

解決策:射出速度と圧力制御用に Moog D941 比例バルブを実装します。

ケーススタディ 2: モバイル機器の精度

解決策:Danfoss PVG 48 比例バルブ システムは、バイナリ コントロールを電子ジョイスティックに置き換えました。

ケーススタディ 3: 製鉄所の精度

解決策:圧延機向けの統合フィードバック制御を備えた ATOS DPZO 比例圧力バルブ。

セレクションガイド

重要なパフォーマンス特性

カタログを参照する前に、次の主要な仕様を確認してください。

- 最大システム圧力 (PSI)

- 必要流量(GPM)

- 使用温度範囲

- 応答時間と精度の要件

- 制御信号種類(電圧/電流/デジタル)

ステップ 2: アプリケーション固有の考慮事項

- 製造:電子機器とフィールドバス通信機能が統合されたバルブを探してください。

- モバイル機器:振動/衝撃に対する定格を備えたバルブを選択し、消費電力を評価します。

- 航空宇宙:冗長フィードバック システムと特殊な材料を備えたバルブを選択してください。

基本については、以下から始めてください

ボッシュ レックスロス ($1,500-8,000):産業オートメーションや工場設備に最適です。インダストリー 4.0 の強力な統合。

パーカー・ハニフィン ($2,000-12,000):交通を誘導するだけでなく、速度制限も制御するスマート交通管制装置。