巨大な建設機械がどのようにして大量のコンクリートを持ち上げるのか疑問に思ったことはありますか?あるいは、自動車工場はどのようにして金属を完璧な形状にプレスするのでしょうか?答えは油圧ステーションです!

これらの驚くべき機械は、私たちが毎日目にする多くの頑丈な機器の動力源です。

油圧ステーションとは何ですか?

油圧ステーションは油圧システムの心臓部のようなものです。心臓が体に血液を送り出すのと同じように、油圧ステーションは特殊なオイルを機械に送り込んで機械を動かします。

それを機械の発電所と考えてください。通常の電力を水力に変換します。これは通常の電力だけよりもはるかに強力です。この水力によって、車を持ち上げたり、巨大なクレーンを動かしたり、金属をさまざまな形状にプレスしたりできます。

油圧ステーションの主な仕事は単純です。

- 機械エネルギーを取得します (電気モーターなどから)

- 油圧エネルギー(圧油)に変える

- そのパワーを重労働を行う必要のあるマシンに送ります

油圧ステーションはどのように機能しますか?

油圧ステーションは、パスカルの法則と呼ばれる単純な科学の法則に基づいて動作します。これを理解する簡単な方法は次のとおりです。水の入った風船を踏むことを想像してください。足からの圧力は踏んだ場所だけにとどまるのではなく、風船の表面のあらゆる部分に均等に圧力がかかります。それがまさに油圧システムが力を増大させる仕組みなのです。

プロセスは次のとおりです。

- モーターが始動します:電気モーターがポンプに動力を供給します

- 圧力が高まります:ポンプはオイルを最大 10,000 psi まで加圧します

- フロー制御:バルブはオイルを作業エリアに送ります

- 仕事が起こる:シリンダー/モーターは圧力を運動に変換します

- 返却サイクル:オイルはフィルターを通ってタンクに戻ります

これにより、庭のホースの圧力よりも 1,000 倍強い力が生じます。

油圧ステーションの主要部品

すべての油圧ステーションには、連携して機能するいくつかの重要な部分があります。

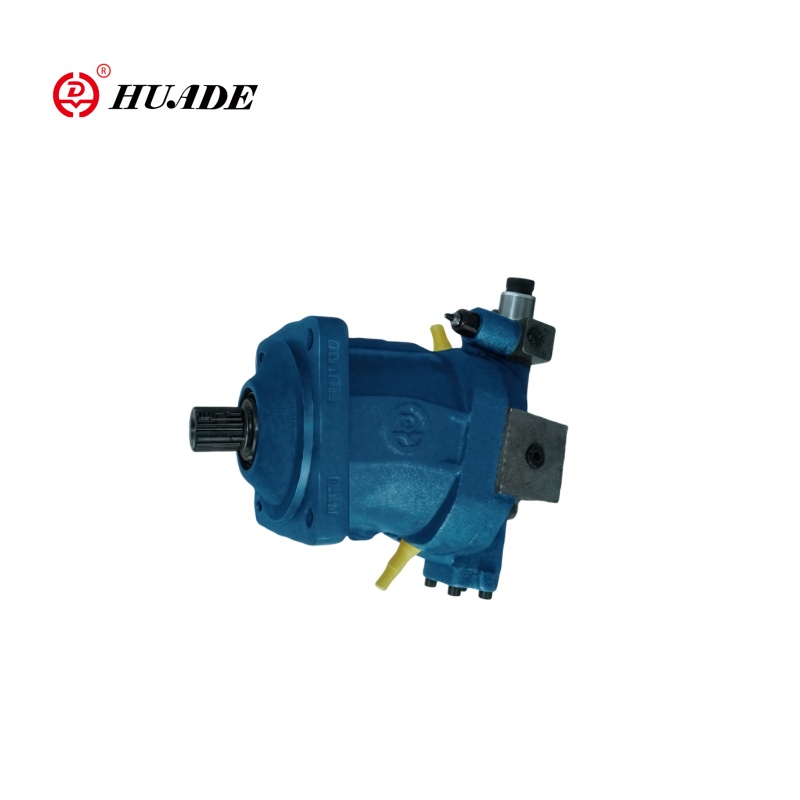

ポンプ

3 つの主要なタイプがさまざまなニーズに対応します。

- ギアポンプ:エンジニアは次のような特有の課題に直面しました。

- ベーンポンプ:静かでパワー調整可能

- ピストンポンプ:最高の圧力能力

モーター

システム全体に電力を供給します。電気モーターは固定設備で主流を占め、ディーゼル エンジンは移動機器に使用されます。

タンク

作動油を貯蔵し、冷却を可能にします。最適なパフォーマンスを実現するために、ポンプ流量の 2 ~ 3 倍のサイズに設定されています。

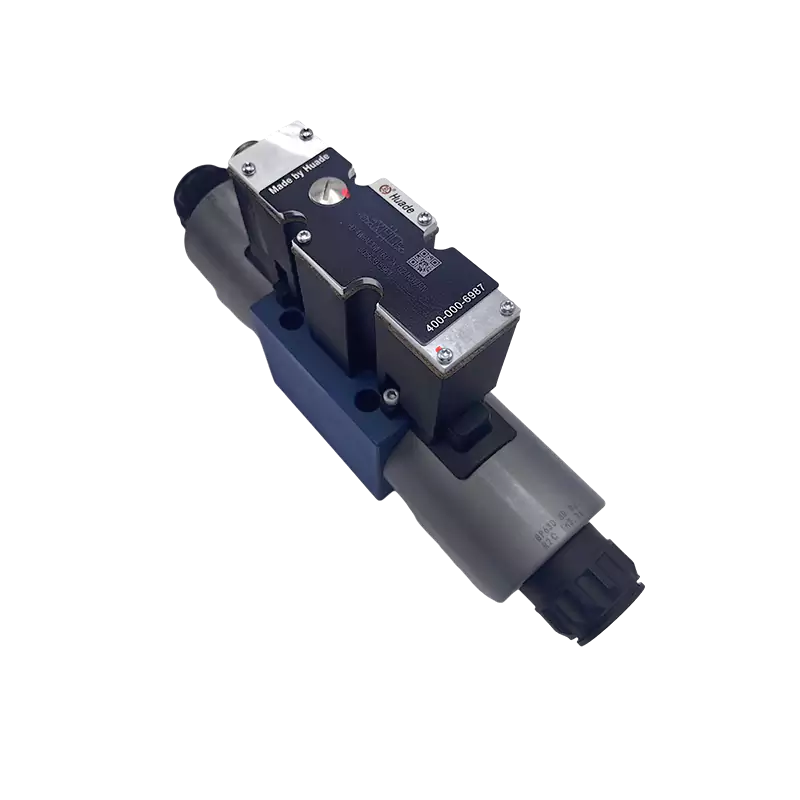

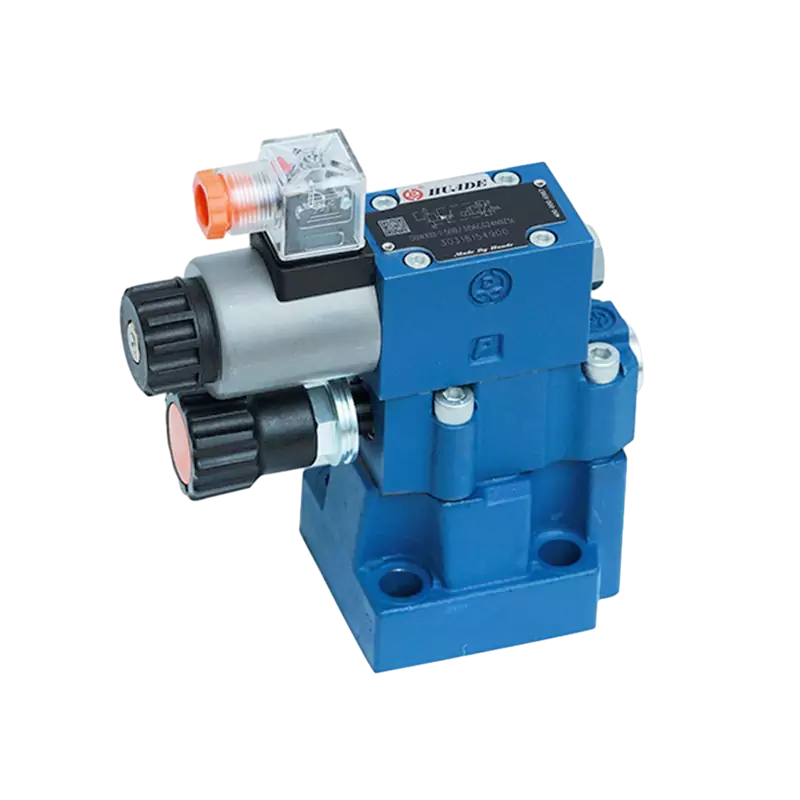

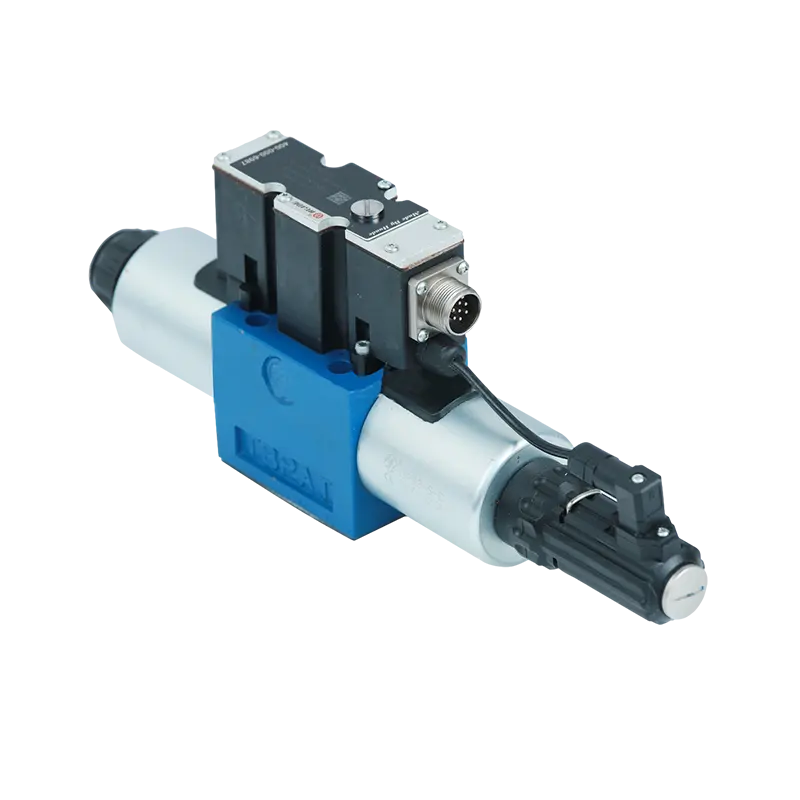

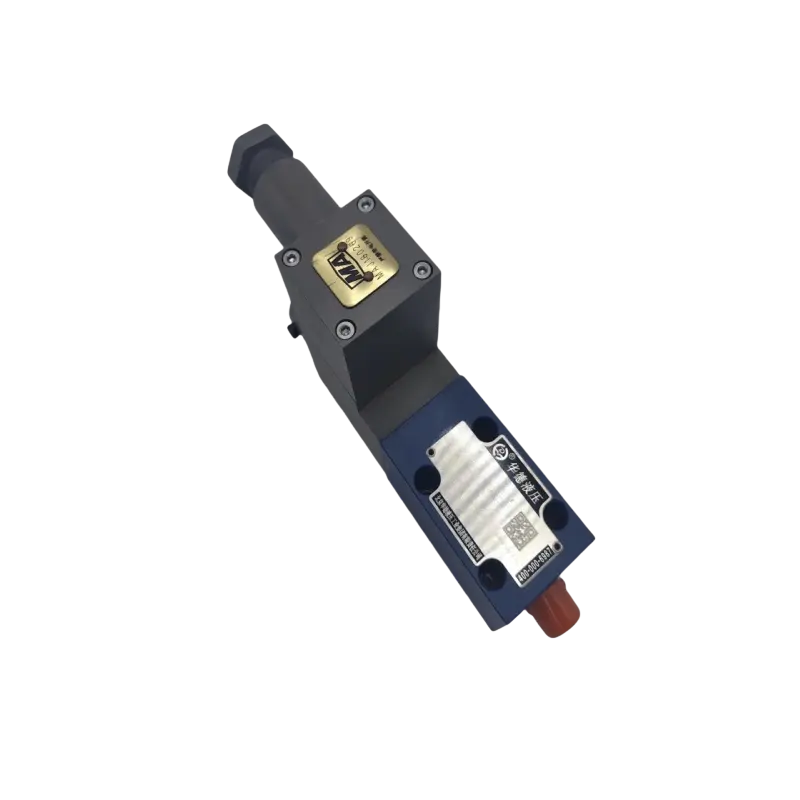

バルブ

システム全体のオイルの流れ、圧力、方向を制御します。

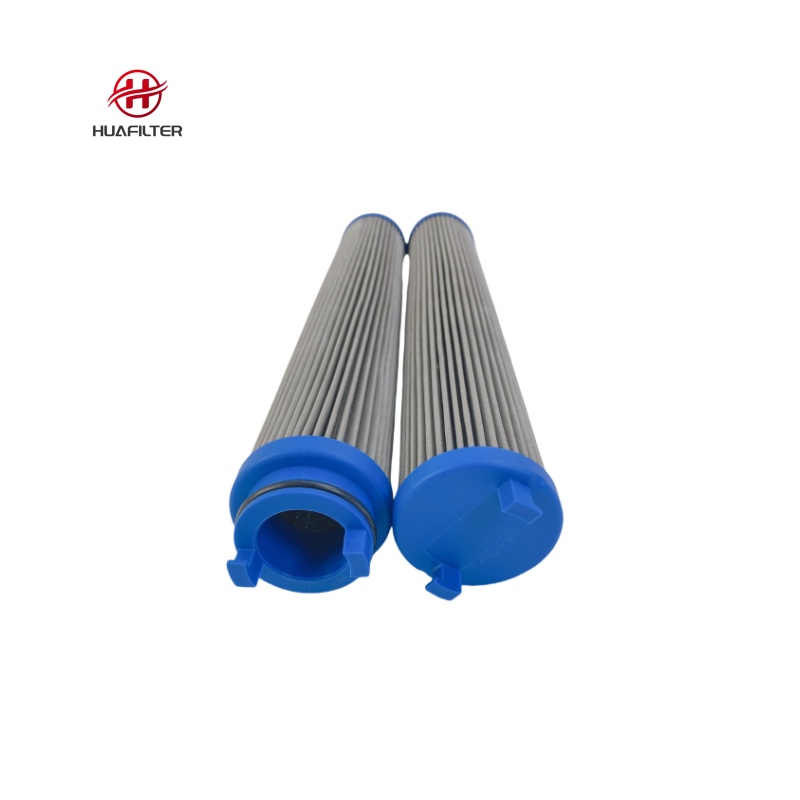

フィルター

汚染物質を除去して、高価なコンポーネントを損傷から保護します。

クーラー

安定した性能を得るために適切な油温を維持してください。

センサー

システムの圧力、温度、オイルの状態をリアルタイムで監視します。

油圧ステーションの種類

すべての油圧ステーションが同じというわけではありません。さまざまな作業に合わせてさまざまなサイズがあります。

コンパクトユニット

- 小型で効率的

- ワークショップや軽機械に最適

- 動きやすい

移動ユニット

- 建設現場向けに頑丈に作られています

- ほこり、雨、衝撃に耐えることができます

- 掘削機、クレーン、農機具に使用

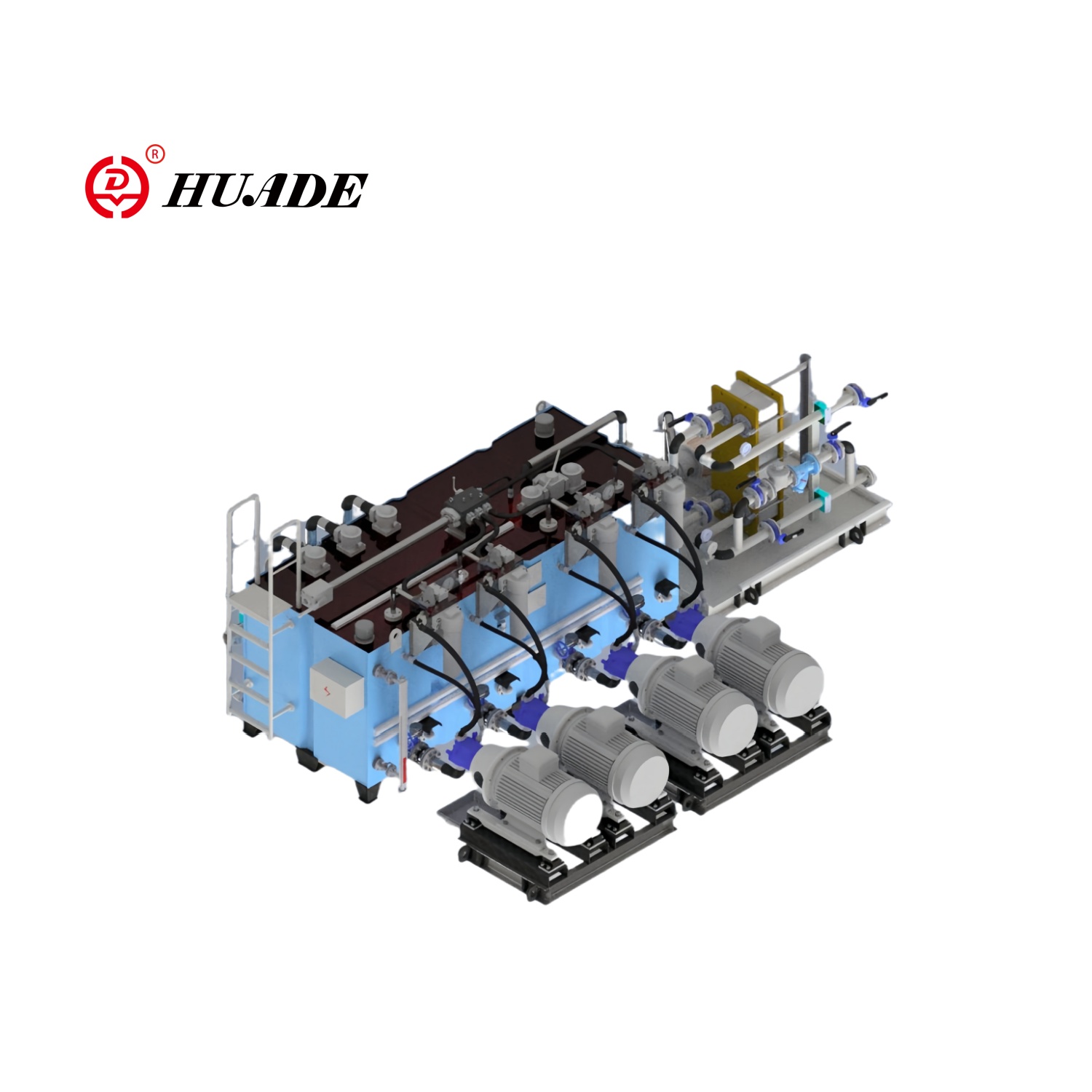

産業用ユニット

- 大きくて力強い

- 工場で最も重い仕事を処理する

- 何時間も止まらずに走り続ける

カスタム単位

- 特殊な仕事のために作られた

- 飛行機や船舶、特殊な機械などに使用されています

ワークショップや軽機械に最適

水力発電所工学の最も印象的な例の 1 つは、ロンドン アイです。この巨大な観覧車は、32 個の油圧ステーションを使用して乗客カプセルを制御します。各ステーションは完璧に機能する必要があります。人々が上空 400 フィートにいる間にステーションが故障した場合を想像してみてください。

エンジニアは次のような特有の課題に直面しました。

- 精密制御:ホイールが回転しても各カプセルは水平に保たれなければなりません

- 耐候性:システムは雨、雪、強風の中でも動作します

- 安全冗長性:複数のバックアップ システムで障害を防止

- 静かな動作:穏やかな乗り心地を邪魔することはありません

結果?非常に信頼性の高い油圧システムにより、ロンドン アイは 20 年以上にわたって安全に稼働し、年間 375 万人以上の訪問者を運び続けています。

油圧ステーションはどこで使用されますか?

油圧ステーションがさまざまな場所で熱心に稼働しているのが見つかります。

工場:自動車部品を成形するプレス機、ペットボトルを製造する機械、製品を移動するコンベアを稼働させます。

ギアポンプ:トラクターが重い鋤を持ち上げたり、収穫した穀物を組み合わせたり、ローダーが干し草の俵を移動したりするのを支援します。

交通機関:修理工場で車を持ち上げたり、飛行機の部品を動かしたり、大きな船を操縦したり。

日常生活:洗車場やゴミ収集車、車椅子リフトにも!

優れた油圧ステーションを設計する方法

油圧ステーションを作成するには、適切なコンポーネントを特定の作業要件に適合させる必要があります。

ステップ 1: ニーズを定義する

- 必要な力と速度

- 動作スケジュール (連続か断続か)

- 環境条件

ステップ 2: コアコンポーネントの選択

- 圧力要件に基づいたポンプのタイプ (3,000 ~ 10,000 psi の範囲)

- 電力ニーズに合わせたモーターサイズ

- 適切な冷却のためのポンプ流量の 2 ~ 3 倍のタンク サイズ

ステップ 3: 制御システムと安全システムを追加する

- コンポーネントの公差に一致するろ過レベル

- 予想される熱負荷に対する冷却能力

- 圧力と温度の監視システム

油圧ステーションの効率化

多くの場合、クーラーの汚れやオイルレベルの低下が原因で発生します。クーラーを掃除し、オイルをチェックします。

可変速度コントロール:これらは、油圧システムのクルーズ コントロールなど、必要に応じてモーターの速度を調整します。

スマートコントロール:いつ電力が必要か、いつ電力を節約できるかを学習するコンピュータ システム。

より良いポンプ:新しいポンプ設計により、エネルギーの無駄が少なく、より正確に動作します。

熱回収:一部のシステムは廃熱を捕捉し、他の目的に使用します。

油圧ステーションの手入れ

他の機械と同様に、油圧ステーションも正常に動作するには定期的なメンテナンスが必要です。

毎日のチェック

- オイルレベルを見てください

- 漏れがないか確認してください

- 何も壊れていないことを確認してください

毎週のタスク

- フィルターインジケーターを確認する

- きれいなコントロールパネル

- 珍しいウェアを探す

月間ジョブ

- 汚れたフィルターを交換する

- きれいな空気取り入れ口

- すべての接続を検査する

年次メンテナンス

- オイルは全部交換してね

- 摩耗したシールを交換する

- すべての安全システムをテストする

よくある問題とその解決方法

適切に維持管理されている油圧ステーションであっても、次のような問題が発生する可能性があります。

低圧:通常は、システムに空気が入ったか、何かが漏れていることを意味します。すべての接続を確認し、空気を抜きます。

過熱:多くの場合、クーラーの汚れやオイルレベルの低下が原因で発生します。クーラーを掃除し、オイルをチェックします。

ノイズの多い動作:通常は、オイル内の気泡、またはポンプが過剰に動作していることを意味します。オイルレベルと入口制限を確認してください。

ゆっくりとした動き:内部漏れまたはバルブの設定が間違っている可能性があります。すべてのバルブをテストし、漏れを探します。

安全第一!

油圧システムは強力であり、適切に取り扱わないと危険になる可能性があります。

- 常に安全メガネと手袋を着用してください

- 高温の表面や高圧ラインには絶対に触れないでください

- 作業エリアを清潔で整理整頓した状態に保つ

- すべての製造元の指示に従ってください

- 機器を操作する前に適切なトレーニングを受けてください

油圧システム内のオイルには非常に大きな圧力がかかっており、実際に皮膚を切り裂いてしまう可能性があります。これらのシステムの力を常に尊重してください。

油圧ステーションの未来

テクノロジーは油圧システムに革命をもたらし、目に見える改善をもたらしています。

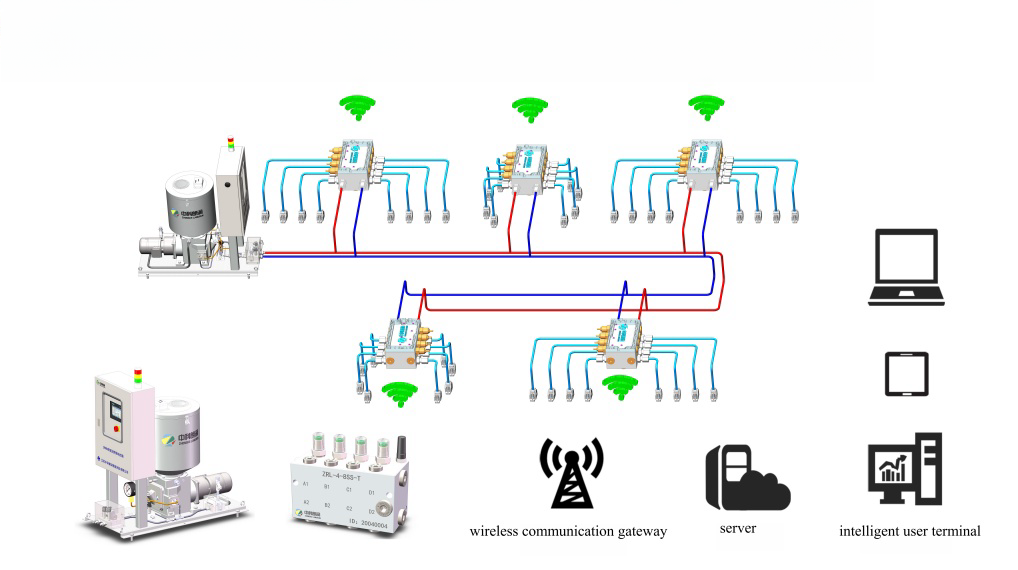

スマート監視システム

- リアルタイムの機器監視により、計画外のダウンタイムが削減されます

- 予知保全システムは予期せぬ障害の 80% を防ぎます

- IoT センサーがオイルの品質とコンポーネントの摩耗を追跡

エネルギー効率の向上

- 可変周波数ドライブによりエネルギー消費を 15 ~ 30% 削減

- パワーオンデマンド システムにより石油使用量を最大 90% 削減

- ハイブリッド電気油圧設計により、全体の効率が 40% 向上

環境改善

- 安定した性能を得るために適切な油温を維持してください。

- クローズドループシステムにより環境汚染を排除

- 熱回収システムは廃棄エネルギーを回収して再利用します

デジタルデザインツール

- 仮想テストにより開発時間とコストが削減されます

- コンピュータシミュレーションにより故障を事前に防止します

- デジタルモデリングにより構築前にシステムパフォーマンスを最適化

注: パフォーマンスの数値は、主要な油圧機器メーカーによって報告された業界標準の改善を表しており、保証された結果ではなく典型的な結果です。

油圧ステーションが重要な理由

油圧ステーションは魅力的ではないかもしれませんが、現代の生活には不可欠です。彼らは私たちの家を建て、食べ物を育て、車を作り、荷物を運ぶのに役立ちます。これらがなければ、建設ははるかに遅くなり、工場は製品を効率的に製造できなくなり、私たちが享受している便利な機能の多くは存在しなくなるでしょう。

次回、超高層ビルを建設するクレーンを見たり、ゴミ収集車がゴミ箱を持ち上げるのを見たりするときは、おそらく舞台裏で懸命に働いている油圧ステーションがあることを思い出してください。

はじめる

油圧ステーションについてさらに詳しく知りたい場合は、以下をご覧ください。

- ビデオを見る:YouTube には、これらのシステムがどのように機能するかを示す素晴らしいアニメーションがあります

- 工場訪問:多くの会社が油圧システムの動作を見学できるツアーを提供しています。

- 授業を受ける:コミュニティカレッジでは油圧システムに関するコースを設けていることがよくあります

- マニュアルを読む:機器メーカーは詳細なガイドを公開しています

- 専門家に相談してください:技術者やエンジニアは知識を共有することが大好きです

油圧ステーションは、単純な物理学と巧妙なエンジニアリングを組み合わせた魅力的な機械です。それらがどのように機能するかを理解することは、現代世界を動かすテクノロジーを理解するのに役立ちます。エンジニアリング分野でのキャリアを検討している場合でも、単に物事がどのように機能するかに興味がある場合でも、油圧ステーションについて学ぶ価値は間違いなくあります。